In the Industry 4.0 era, machine reliability has become a crucial pillar for maintaining productivity and operational efficiency. Unreliable machines will cause downtime, increase maintenance costs, and reduce production output. Therefore, the concept of Reliability Improvement is shifting, not only relying on traditional preventive maintenance but also utilizing Big Data and Internet of Things (IoT) technology.

Reliability Challenges in Conventional Industry

Before the advent of digital technology, reliability improvements were typically achieved through:

- Rigid preventive maintenance schedules (based on operating hours).

- Regular manual inspections by technicians.

- Failure analysis after damage occurs (reactive approach).

The downside of this approach is that over-maintenance often occurs or potential damage is detected too late.

The Role of IoT in Reliability Improvement

With the advent of IoT (Internet of Things), machines can be equipped with smart sensors that continuously transmit real-time data. For example:

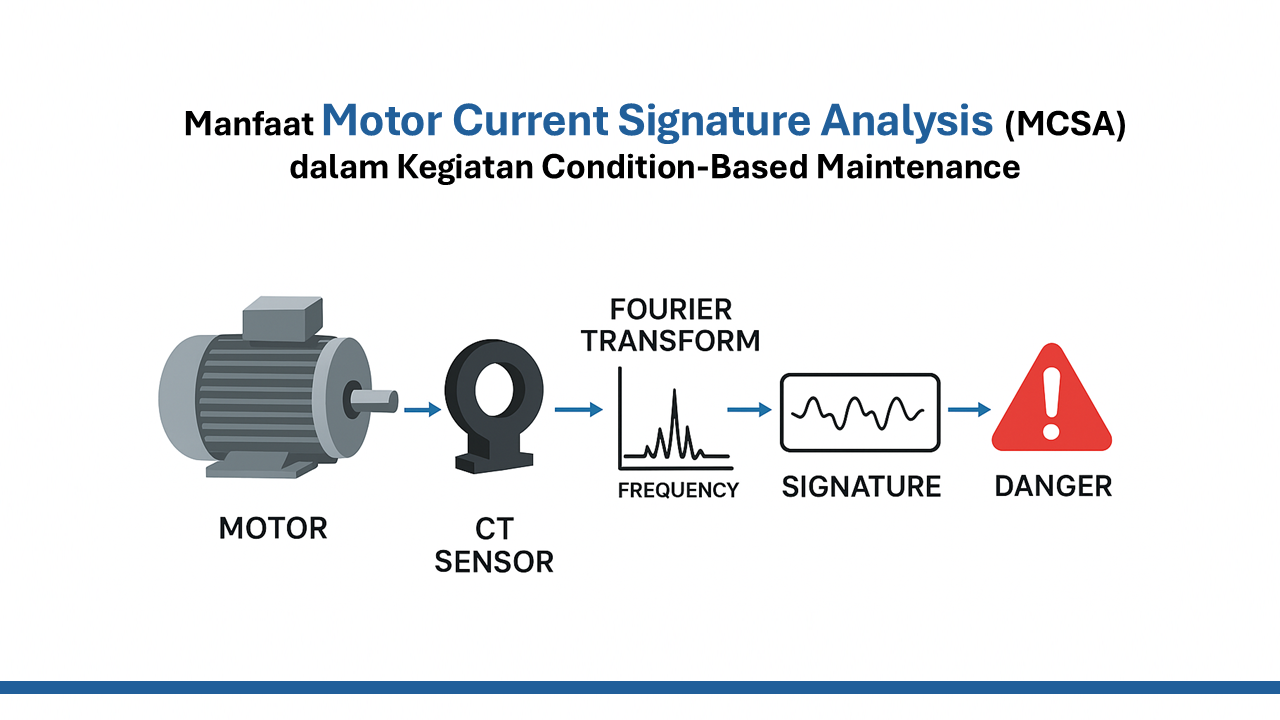

- Vibration sensors → to detect rotor imbalance or worn bearings.

- Temperature sensors → to monitor overheating in electric motors.

- Pressure and flow sensors → to monitor the condition of pumps or hydraulic systems.

Data from these sensors is sent to a centralized system or the cloud, where it is analyzed in real time. This allows the maintenance team to know the actual condition of the machine at all times.

Big Data and Predictive Analytics

Machine reliability is further enhanced by Big Data analytics. Large volumes of data from hundreds or even thousands of sensors are analyzed using statistical and machine learning algorithms.

- Predictive Maintenance: predicting when a component will fail before it actually fails.

- Anomaly Detection: detecting abnormal data patterns as an early indication of a problem.

- Root Cause Analysis: accelerating the identification of the root cause of failure.

For example, historical bearing vibration and temperature data can be used to build predictive models. These models can alert technicians before bearing failure occurs, thus avoiding downtime.

Benefits of Reliability Improvement with Big Data & IoT

1. Reduced Downtime → failures are detected more quickly.

2. Cost Efficiency → Maintenance is carried out according to machine condition, not just according to a schedule.

3. Safety Improvement → Potential hazards can be anticipated earlier.

4. Asset Optimization → Extended machine lifespan due to more precise maintenance.

Implementation in Industry

Big Data and IoT-based reliability improvements have been implemented in various sectors:

- Manufacturing: monitoring CNC machines, compressors, and conveyors.

- Energy: predictive maintenance on gas turbines and generators.

- Mining: sensors on slurry pumps, conveyor belts, and heavy equipment.

- Oil & Gas: monitoring pumps, valves, and other rotating equipment.

Reliability Improvement in the Industry 4.0 era is no longer simply about keeping machines running, but also integrating digital technology to maximize asset performance. The combination of IoT and Big Data enables companies to shift from reactive maintenance to predictive and proactive maintenance, ultimately increasing productivity, lowering costs, and extending asset life.