In modern industry, equipment reliability is key to maintaining efficiency, safety, and production continuity. One maintenance approach that is increasingly being implemented is Condition-Based Maintenance (CBM) — a maintenance strategy based on the actual condition of the equipment, rather than a specific time schedule.

One technique that has proven effective in this approach is Motor Current Signature Analysis (MCSA).

What is Motor Current Signature Analysis (MCSA)?

MCSA is a non-invasive diagnostic method that analyzes the motor's electrical current pattern to detect various mechanical and electrical faults in induction motors without requiring operation to be halted.

By monitoring the current spectrum in the motor phases, the system can identify small changes in the signal that indicate internal faults — such as unbalance, bearing wear, damaged rotor bars, and eccentricity problems.

Brief Working Principle

Electric motors work by converting electrical energy into mechanical energy. Any disturbance in the mechanical or electrical system will cause changes in the current characteristics.

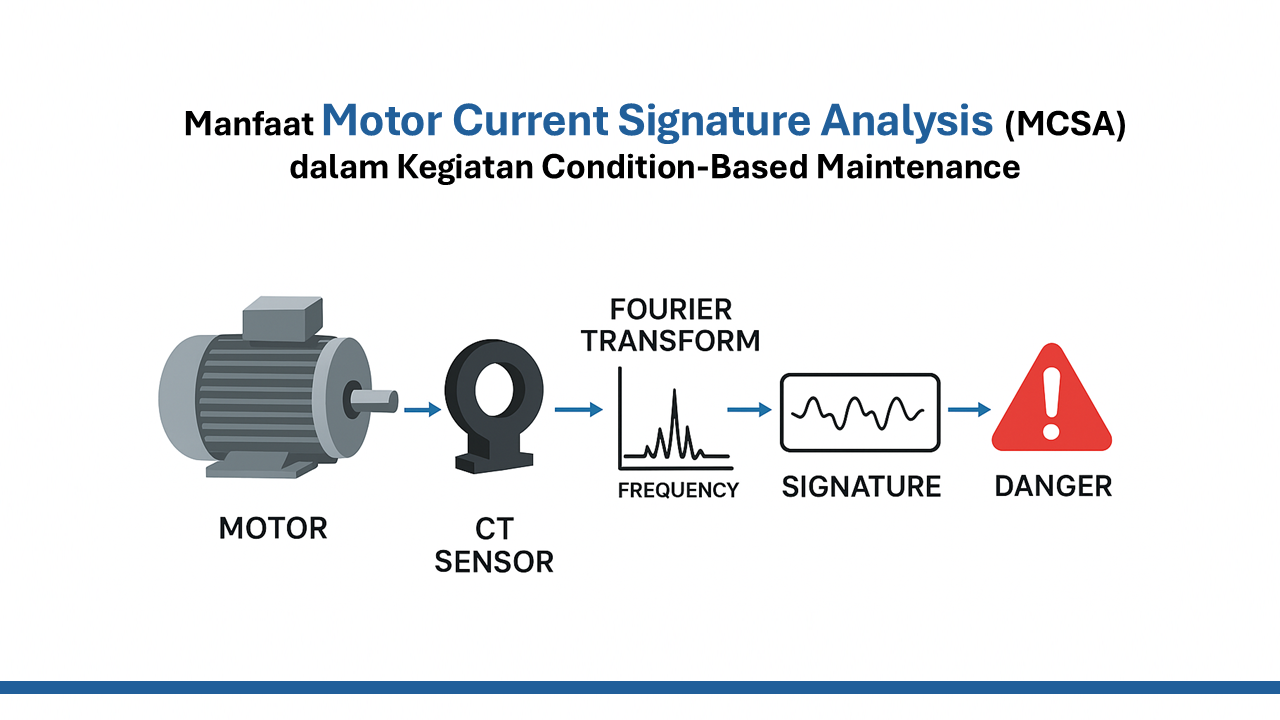

MCSA analysis is performed by:

- Obtaining the motor current signal using a current sensor (CT sensor).

- Perform a Fourier transform (FFT) to convert a time signal into a frequency spectrum.

- Identify signature frequencies that indicate a specific type of failure.

For example:

- Broken rotor bar → sidebands appear around the slip frequency.

- Bearing fault → mechanical vibration signals are reflected at certain harmonics.

- Unbalance/misalignment → additional frequencies appear around 1× or 2× the line frequency.

Benefits of MCSA in Condition-Based Maintenance

- Early detection without stopping the motor

MCSA can be performed online, meaning the motor continues to operate normally while the analysis is taking place—very efficient for continuous process industries.

- Reduced downtime and maintenance costs

By knowing the actual condition of the motor, maintenance can be performed in a timely manner—not too early (which is costly) or too late (which risks fatal damage).

- Simultaneously assess the condition of the rotor, stator, and connected loads

MCSA provides a comprehensive overview of the electromechanical system, including disturbances that may originate from the pump, gearbox, or compressor driven by the motor.

- Easy integration with digital monitoring systems (IoT/SCADA)

Current data can be collected in real time and processed by predictive analytics systems, enabling 24/7 monitoring and automatic notification when anomalies are detected.

- Supports data-driven maintenance decisions

MCSA provides quantitative data that can be used to determine maintenance priorities, estimate remaining motor life, and establish long-term performance trends.

Motor Current Signature Analysis (MCSA) is one of the most efficient methods for implementing Condition-Based Maintenance.

With the ability to detect faults early, without direct intervention on the motor, MCSA not only improves system reliability but also optimizes maintenance costs and time.

In the Industry 4.0 era, the integration of MCSA with digital monitoring systems makes it an essential tool for intelligent and continuous predictive maintenance.

Currently, Electrical Signature Analysis is an extension of Motor Current Signature Analysis, which offers broader analysis capabilities, including voltage and a wider range of electrical parameters. It is well-suited for multi-fault diagnostics, including electromechanical combinations, especially in modern systems with inverters.