Filter Plugging Tendency (FPT) is an important parameter in assessing the quality of diesel and biodiesel fuel. FPT indicates the extent to which a fuel can clog the fuel filter due to the formation of wax crystals or solid particles, especially at low temperatures. This test is crucial because a clogged filter can cause the engine to lose power, waste fuel, or even stall.

Why is the Filter Plugging Tendency Test Important?

- Ensures engine reliability → prevents fuel supply interruptions.

- Determines the cold flow properties of biodiesel, which are typically poorer than fossil diesel.

- Determines quality standards for biodiesel's suitability for use in certain climates and conditions.

- Assists in fuel formulation with cold flow improver additives or fossil diesel blends.

Basic Test Principles

The Filter Plugging Tendency test essentially measures the lowest temperature at which fuel can still pass through a standard filter within a specified time. If the fuel fails to pass through the filter, it indicates a clogging risk at that temperature.

Commonly Used Test Methods

1. ASTM D6371 – Cold Filter Plugging Point (CFPP) Test

This is the most commonly used method for FPT testing.

- The fuel sample is cooled in a controlled manner.

- At specific temperature intervals, the fuel is tested to see if it can still flow through a standard filter within a maximum of 60 seconds.

- The lowest temperature at which the fuel still passes through the filter is recorded as the CFPP.

2. IP 309 (Institute of Petroleum, England)

Almost identical to ASTM D6371, with some minor differences in the equipment and cooling procedures.

3. Filter Blocking Tendency (FBT) Test – ASTM D2068

Unlike CFPP, this method focuses more on measuring the level of filter clogging due to solid particles at a specific pressure. The result is a numeric index indicating the level of plugging.

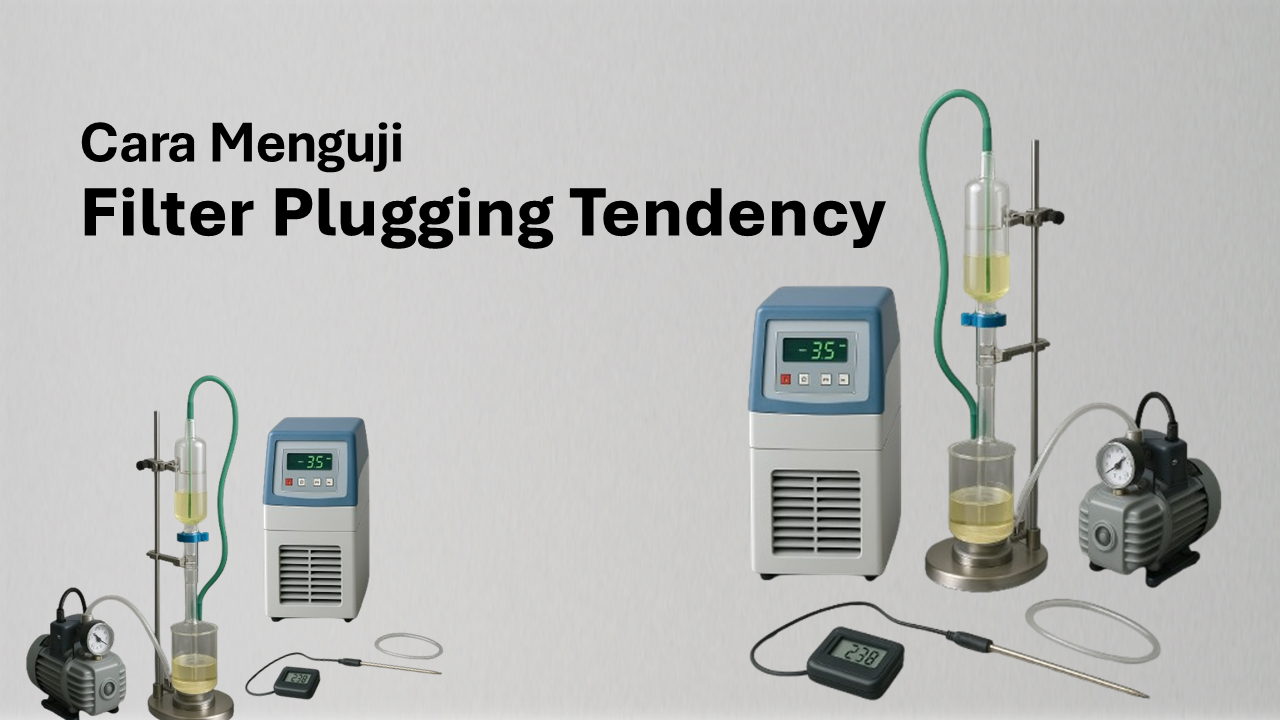

Equipment Used

• Cold Bath/Chiller → to gradually cool the fuel sample.

• Standard Filter → usually a mesh with a specific size according to the test standard.

• Pump/Vacuum → to draw fuel through the filter.

• Timer → records the time it takes for the fuel to pass through the filter.

• Digital Thermometer/Probe → accurately monitors the sample temperature.

Short Steps of the CFPP Test (ASTM D6371)

• Sample Preparation → Place the biodiesel/diesel into the test tube.

• Gradual Cooling → Reduce the temperature according to the standard cooling rate.

• Filtration Test → At specified intervals (e.g., every 1°C), attempt to draw fuel through the filter.

• Recording Results → The last temperature at which the fuel can still pass for ≤ 60 seconds is recorded as the Cold Filter Plugging Point (CFPP).

Factors Affecting Results

- Type of biodiesel feedstock (palm, soybean, canola, etc.).

- Blending content (B20, B30, B40, etc.).

- Presence of cold flow improver additives.

- Sample cleanliness from water or contaminants.

Filter Plugging Tendency testing is a critical step in ensuring biodiesel can be used safely under various temperature conditions. Using standard methods such as ASTM D6371 (CFPP) or ASTM D2068 (FBT), producers and users can identify potential filter clogging risks early on. These test results also assist the government in establishing biodiesel quality standards in Indonesia to ensure it remains environmentally friendly and reliable for engines.