In your activities, of course, requires a variety of basic things, such as water, fire, to electricity. Fortunately, with existing technology, these basic things can be met. One of them through power generation.

For the power plant itself, it is usually built and run to produce electricity so that it can be supplied to people's homes. Quite a number of types of power plants are created and used today, such as Hydroelectric Power (PLTA), Solar Power Plants (PLTS), Gas Power Plants (PLTG), Geothermal Power Plants (PLTB), Diesel Power Plants (PLTD), Wave Power Plant (PLTO), and Steam Power Plant (PLTU). For the power plant itself, there is one component in it that is very important, namely the steam turbine.

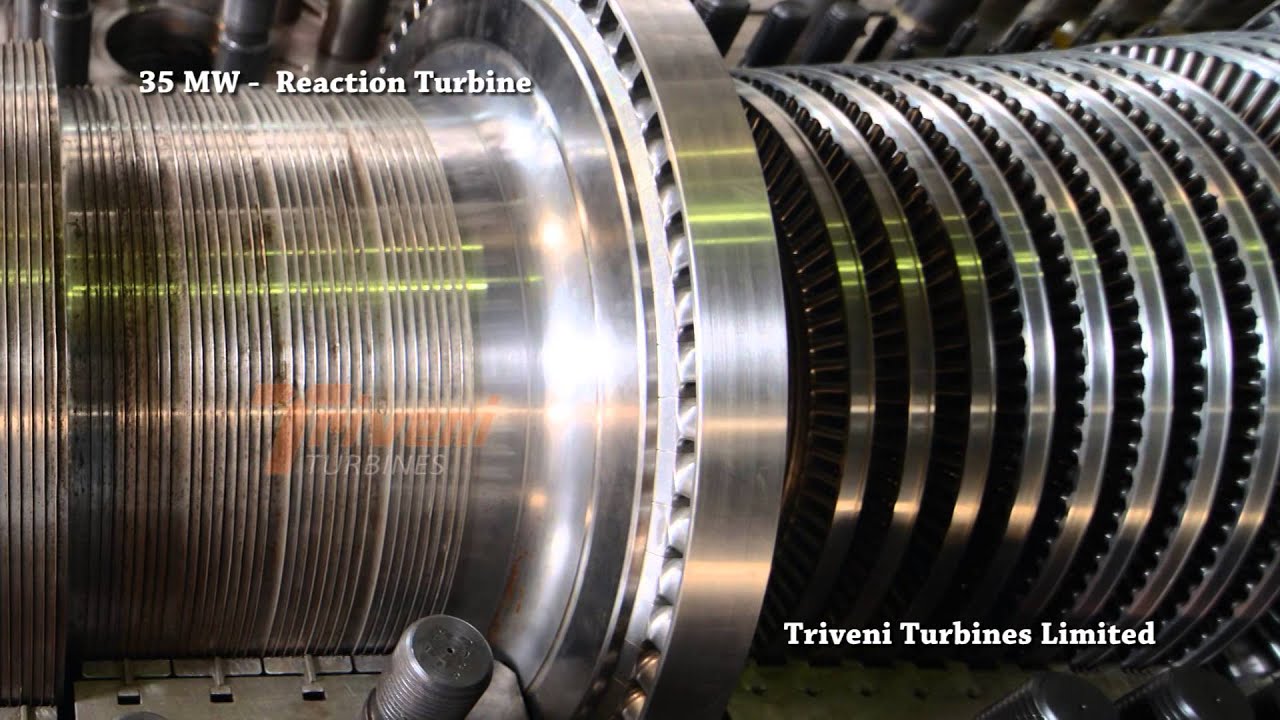

What is Steam Turbine?

Basically, the working principle of a steam turbine is an initial mover that is useful for converting existing potential energy into kinetic energy. This kinetic energy is then converted to become mechanical energy that is formed in a turbine shaft rotation.

Furthermore, the turbine shaft is connected with a mechanism that is driven, can be directly or with the help of other elements. With such a working mechanism finally, a steam turbine can be useful to become a power plant. Steam turbines have become a very important component in the existence of a power plant. Without a steam turbine, it is difficult to be able to get the desired electric power.

Steam Turbine Components

In the steam turbine itself, there are quite a number of components, each of which is useful to provide good performance. Each of these components together to produce steam in the right amount so that it can be converted into electricity. There are eight components of a steam turbine, namely:

Casing

As the name implies, the casing is used to be the main cover of the parts in the steam turbine. With the casing, the steam turbine component is not directly exposed from the outside so it remains durable.

Rotor

There is no steam turbine without a rotor. The rotor is the part of the turbine that rotates and is quite a lot. There are two parts of the rotor in the steam turbine, the Rotor Shaft (serves as a component for the installation of discs along the axis) and the Rotor Blades (functions as a receiver for the force of steam kinetic energy).

Disc

The disc has a function as a place where the blades are installed radially between the shafts.

Nozzle

The nozzle is useful for steam expansion media which can later convert existing potential energy into kinetic energy.

Bearings

The bearings inside the steam turbine are useful for supporting both ends of the shaft. Besides that, it is also useful as a receiver of the burden caused.

Seal

A seal is used to prevent undesirable things such as steam leakage. Usually, the seal is installed around the shaft.

Clutch

The coupling functions as a link between the work of a steam turbine with a mechanism that is driven by a steam turbine.

Quite a lot of components exist in steam turbines, but steam turbines remain a major requirement in the industry today.

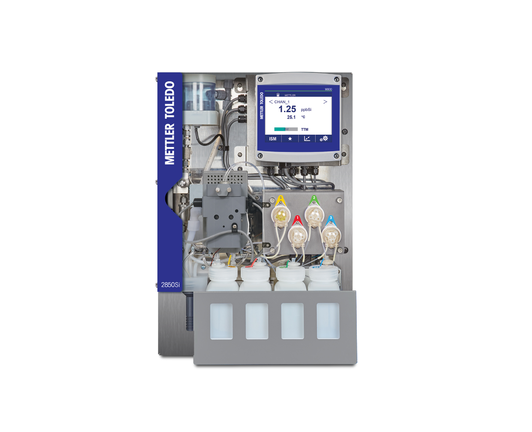

To be able to learn how to operate a steam turbine properly, one can use a boiler simulator and a steam turbine made by Weel and Sandvig from Denmark.