To drive a variety of equipment for industrial use, you can use a pneumatic system. This drive system is different from the hydraulic system. If the hydraulic system utilizes a fluid medium (usually oil), the pneumatic system utilizes compressible air (compressed air). Following is an explanation of pneumatic systems.

Get to Know the Pneumatic System

Pneumatic system is a drive system that uses air as its main working media. Air was chosen because besides the unlimited amount, the price was relatively cheaper when compared to the fluid used in hydraulic systems. Even so, its ability to move equipment is comparable.

Air that is used as a working medium in a pneumatic system is not as airy as air, but it is air that has been compressed (compressed). Usually what is used is compressed dry air (through the air dryer drying process). However, it is not uncommon to find pneumatic systems that use a mixture of air with atomized oil so that the actuator components remain well lubricated.

Characteristics of Pneumatic Systems

The main characteristic of a pneumatic system is the process of compressing air as a first step. The air that has been inhaled from the atmosphere and collected is reached until it reaches the desired working pressure. When air is obtained, the temperature tends to rise.

After being loaded, the air is cooled with an air dryer. The aim is to dry the air. The air is then stored under pressure. When needed later, the air will be allowed to expand until it reaches the object. The remaining air from this expansion will then be returned to the atmosphere.

Pneumatic System Components

To work, pneumatic systems require a series of components. Following are some common components found in pneumatic systems.

Compressor

As mentioned in the previous point, pneumatic systems use air that has been obtained as the main working medium. This compressor component is used to get air. In addition, the compressor is also tasked with maintaining the air pressure remains at the bleached working pressure.

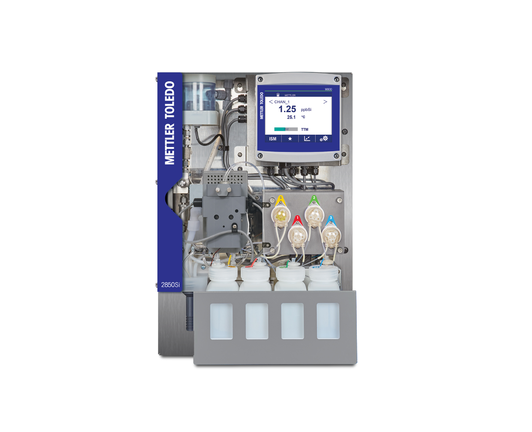

Gauge and Regulator

In order for the pneumatic system to continue to function according to its function, the working media must be continuously monitored. These two components have the task of being the "control". The gauge is assigned to show the level of air pressure, while the regulator is to control the amount of working media (compressed air) that enters the pneumatic system.

Control Valve

The check valve (check valve) functions as a barrier that prevents backflow of compressed air. This component will prevent air from re-entering the compressor when it is processed in a buffer tank.

Directional Valve

A directional valve acts as a regulator of the air flowing in and out of the actuator. That way, the work of the actuator can be more stable. There are two kinds of directional valves, namely mechanical and electrical.

BufferTank

Buffer tanks are components that function as storage of compressed air reserves. Another function is to help balance the compressor's work in applying pressure to the air.

Actuator

In a way, this component is the most important part in a pneumatic system. Without an actuator, a pneumatic system will not be able to produce motion. In its utilization, there are several actuators including pneumatic cylinders and pneumatic motors.

Liquid / Gas Coalescer

Serves to capture very fine water droplets found in pneumatic systems, commonly used at point of use to protect critical instruments or components and Pall is one of the well-known liquid / gas coalescer makers.

Pneumatic system is one of the work systems that can move objects in industrial purposes. From this it follows that this system works by utilizing compressed air (through the process of compressing air). Pneumatic systems are considered more efficient because the media work in the form of relatively cheaper air. If you are interested in using a pneumatic system, get the components through Hyprowira.