When analyzing fluid cleanliness levels based on ISO standards, there are several important things that need to be considered. Here is a general guide that covers the important steps and key aspects to pay attention to:

1. Selection of Relevant ISO Standards:

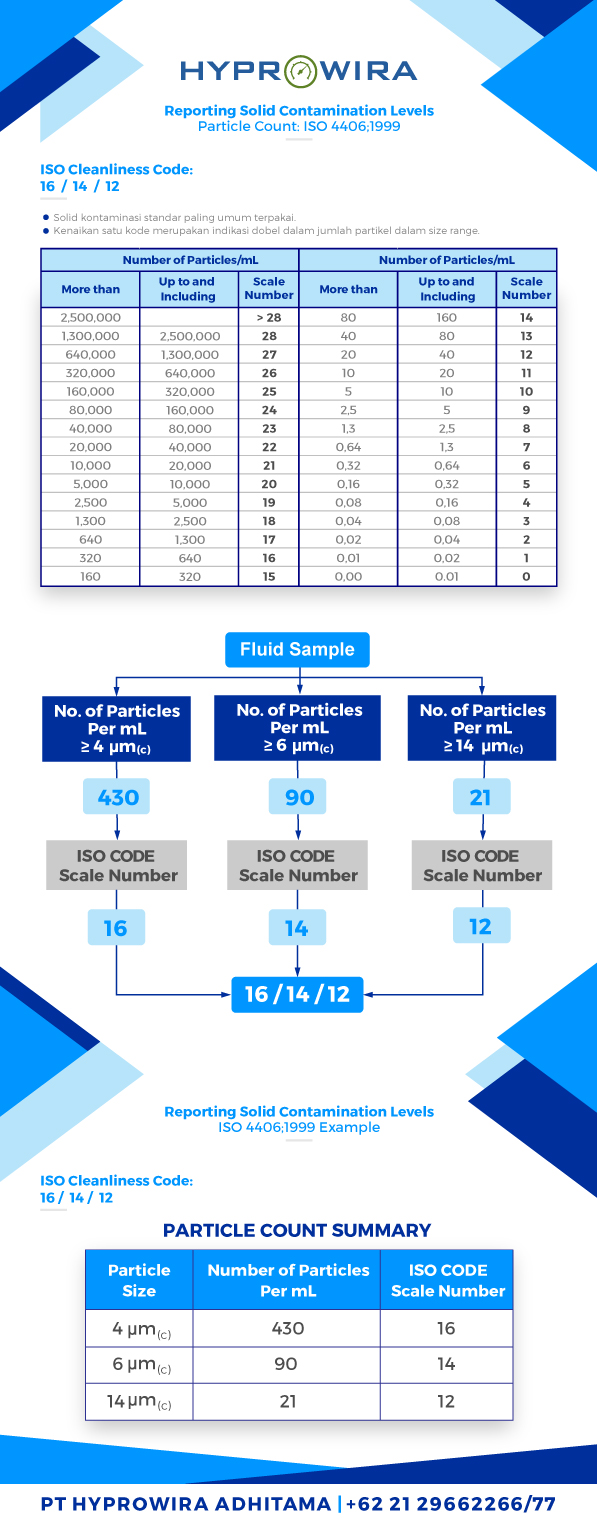

o ISO 4406: This is the most commonly used standard for measuring the cleanliness level of hydraulic fluids and lubricants based on the number of particles of a certain size.

o ISO 11171: This standard specifies calibration methods for automatic particle counters used in fluid cleanliness analysis.

2. Equipment Preparation:

o Ensure that all equipment used, such as particle counters, microscopes or other analytical tools, is properly calibrated according to relevant ISO standards.

o Use clean sampling containers and tools to prevent contamination.

3. Sampling:

o Take fluid samples from representative points in the system. Avoid areas that may have local contamination or excessive turbulence.

o Use appropriate sampling techniques to ensure samples are not contaminated during the collection process.

4. Sample Transportation and Storage:

o Store samples in a clean and tightly closed container to prevent outside contaminants from entering.

o Avoid exposing samples to extreme conditions, such as excessively high or low temperatures, which could affect the analysis results.

5. Analysis Method:

o Use analysis methods that comply with ISO standards. For particle analysis, commonly used methods are automatic particle counters or microscopic analysis.

o Ensure analysis procedures are carried out in a clean environment to prevent contamination.

6. Calibration and Validation:

o Calibration of particle counters should be carried out routinely using recognized reference standards, in accordance with ISO 11171.

o Validate the method to ensure the accuracy and precision of the analysis results.

7. Results Reporting:

o Report the results of the fluid cleanliness analysis in a format that complies with the ISO 4406 standard, usually in the form of an ISO cleanliness code (example: 18/16/13).

o Include any additional relevant information, such as the time of sampling, sampling location, and analytical method used.

8. Monitoring and Follow-up:

o Based on the analysis results, carry out regular monitoring of the fluid cleanliness level.

o If high levels of contamination are found, determine the steps necessary to correct the problem, such as additional filtration, system maintenance, or fluid replacement.

By following the procedures and standards set by ISO, you can ensure that fluid cleanliness analysis is carried out properly and produces accurate and reliable data.