1. Sample: not intended for turbine oil samples with the addition of dyes

2. Sample container: use Amber bottle, wide mouth HDPE and keep it away from UV light exposure.

Note: Fluorescent light also contains UV components and can increase deposit levels

3. Equipment: a tool to determine dE has specifications, namely a Spectrophotometer which has 0°/45° geometry, a spectral interval resolution of 10 nm and is in visible light with a range of 400-700 nm.

4. Solvent : Petroleum Spirit which has BP (boiling point) 35 – 60 ° C

5. Sample preparation:

a. Samples must be heated at a temperature of 60 – 65 ° C for 23 – 25 hours

b. After that, the sample was incubated by allowing it to stand at room temperature of 15 – 25 °C with a range of 68 – 78 hours (Incubation was carried out in conditions not exposed to UV light).

6. Draw down / Filtration :

a. Pore ??size membrane filter used: 0.45 um diameter 47 mm and 0.22 um diameter 25 mm

b. Comparison of sample volume : Solvent = 50 mL : 50 mL

7. Drying of the membrane after filtration is carried out in a desiccator for ± 3 hours

8. Determination of the color of the membrane: dE

a. Spectrophotometer setting with CIE LAB 1976 . output

b. Before capturing the sample membrane, do a blank capture first

Note: The procedure for making blanks: 50 mL of solvent is filtered, the membrane is dried in a desiccator and the dE value is captured.

c. When capturing membranes, do not do it with the condition of the room being too bright (under the lights) or too dark

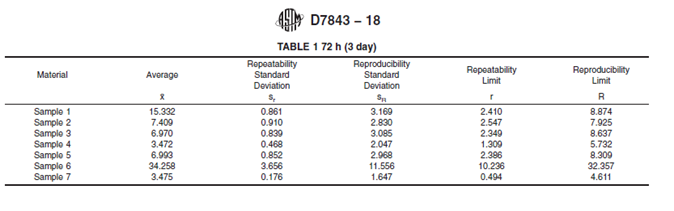

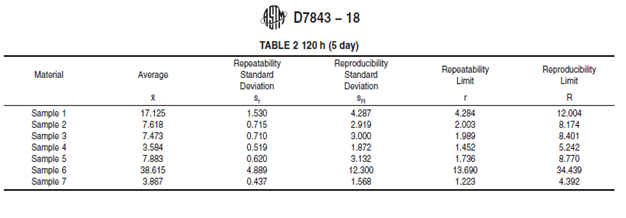

Table Comparison of incubation time that affects the value of dE (data based on ASTM D 7843)