Working with heavy equipment must of course pay attention to his well-being. So that heavy equipment can be used for a long period of time, the oil used as a lubricant must be of good quality. How to check the quality of the lubricant used is by analyzing the oil in the laboratory of chemicals. The next problem is how to read the results of the oil analysis that has come out? Here are some things that need to be known in reading the results of oil analysis for lay people.

Fill In the Report in General

In general, the results of the lab analysis of the oil samples sent contain the results of the test and also brief recommendations. But because the lab examiner does not know the engine condition in real terms and also the history of its use (because it is not its authority to operate the equipment), the reported test results are general and not so specific.

Parts of the Analysis Report

Generally the oil analysis report is divided into three parts, namely liquid properties, contamination, and engine debris found on the engine after oil is used. For the liquid property section, the contents are reports on the physical condition of the oil when tested and also its chemical conditions and determine the remaining life of the product (RUL).

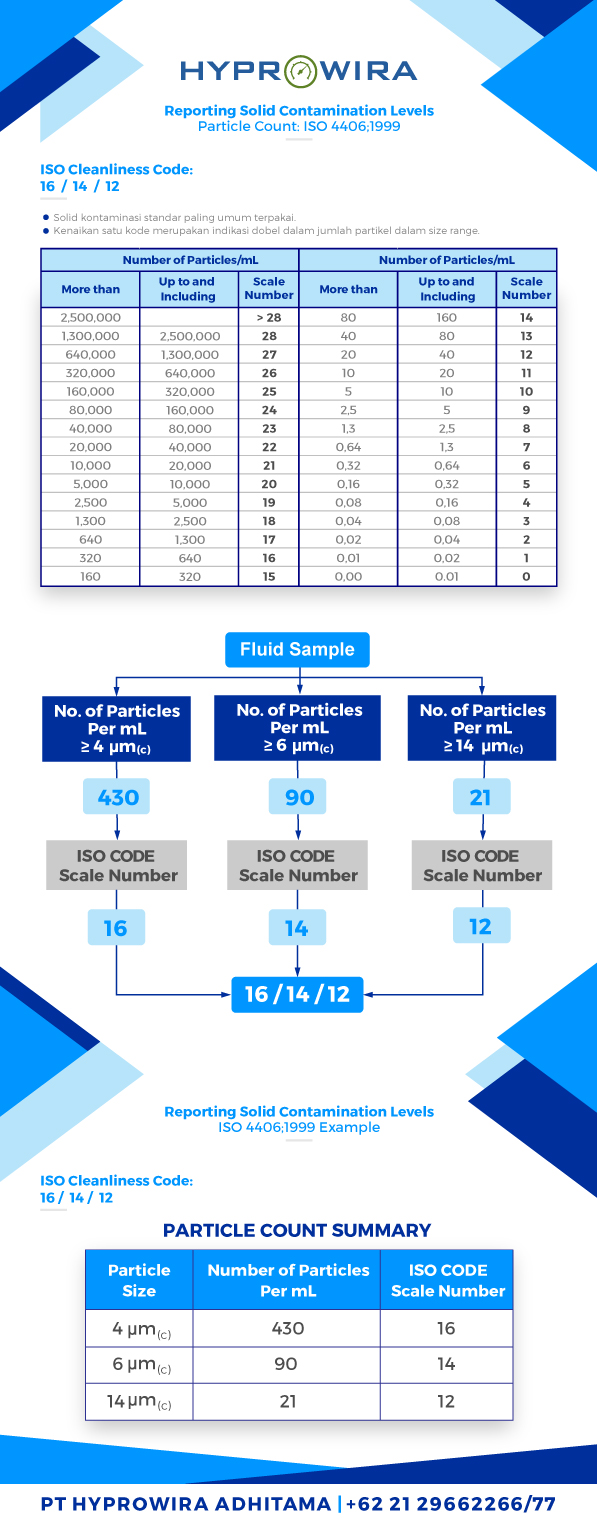

Data on the oil analysis report will also reveal data about the cleanliness of the oil, whether it contains contaminating material that damages or not and analyzes the causes of contamination both externally and internally. Then the third one, which is debris or wear debris, describes the analysis of the remains of the engine mechanism, is there corrosion, or other machine degradation.

Other elements commonly found in oil analysis include:

- Indicator of viscosity

- Acidity level

- Fourier transform infrared (FTIR)

- element analysis

- Particle calculation, and

- Analysis of oil humidity.

Which Must be Considered When First Reading the Report

When the oil analysis report has arrived at you, the first thing you should check is the suitability of the oil tested with the tool from which the oil sample was taken. This is important to measure the effectiveness of lubricants with the engine used mainly because of the use of one engine with another engine even though the exact function and shape is not necessarily the same performance. Then in the second part you can see a report about the size of element contamination that occurs in the oil. From the increase in the level of certain chemicals can be analyzed the cause.

After the oil analysis report presents numerical data about the physical condition and other indicators of the oil sample tested, at the end of the report you will find recommendations that are concluded from the test results. But as mentioned earlier, this recommendation should not be applied outright because the testers do not know the exact condition of the machine tool using the oil sample.