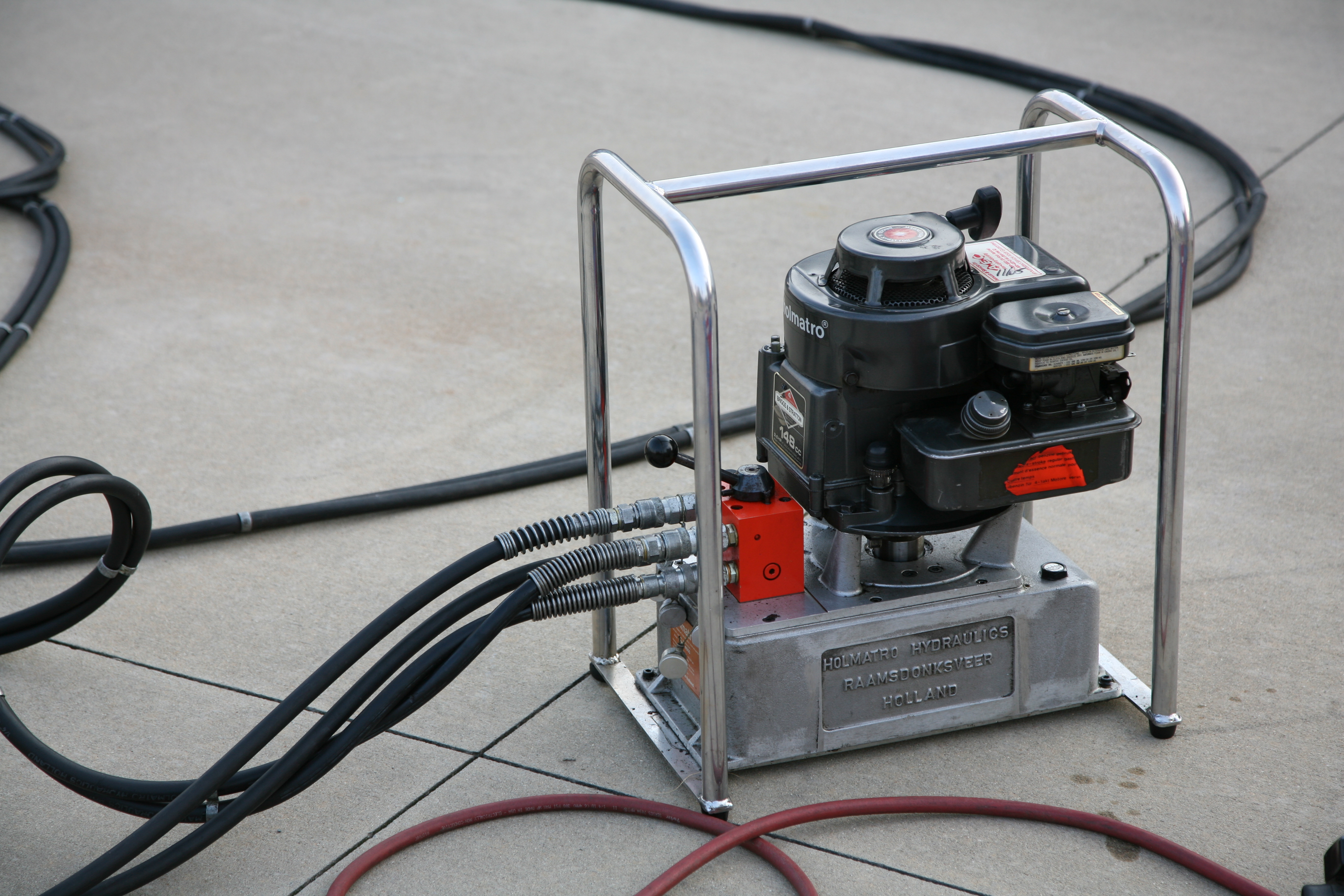

Hydraulic is a work system commonly used on heavy equipment such as cranes, excavators, bulldozers, forklifts, and many others. This system moves by utilizing fluid as its energy. Hydraulics is also closely related to Pascal's Law which reads, "the pressure exerted on a liquid in a container will be transmitted in all directions with the same power." Since “only” relies on pressure and fluid, let's find out what are the advantages and disadvantages of hydraulic systems used in various machines.

Advantages of the hydraulic system

Talking about the advantages and disadvantages of hydraulic systems, let's first discuss the advantages. Even though it seems that the hydraulic system only relies on fluid and pressure to be distributed in all directions, this working principle is proven to be able to lift heavy materials. Here are ten advantages of a hydraulic system:

1. Any hydraulic motion is independent of the load as long as the fluid is not subject to resistance and a flow control valve can be used.

2. Precision and flexible.

3. Can move large power using only relatively small components.

4. Can move freely when lifting large loads.

5. Easy to use and friendly control system. Beginners who are just learning to operate heavy equipment with a hydraulic system will find it easy to understand.

6. The operation is smooth, does not cause unnecessary noise and vibration on the machine.

7. The design and design is simple.

8. Can be rotated in the reverse direction (reversible).

9. Make it easy to move heavy material, one lift, or move goods up to tons of weight.

10. The service life is quite long so it can save the cost of purchasing new equipment.

Weaknesses of the hydraulic system

It is incomplete to discuss the advantages and disadvantages of hydraulic systems without showing the shortcomings of the working principle of this system. After the advantages, now we will describe the weaknesses of the hydraulic system. Even though there are shortcomings, it doesn't mean that this hydraulic system is bad. It's just that, every working principle on heavy equipment must have advantages and limitations.

1. Hydraulic systems require intensive and periodic maintenance.

2. Systems frequently require parts with a very high degree of precision.

3. A small leak in the hydraulic pipeline will be fatal to the transfer of power. This causes

4. the risk of accidents increases.

5. The high pressure received by the fluid can also cause work accidents if the power is too high and the pipeline is unable to withstand the power delivered by the fluid.

Machine hydraulic system maintenance

As previously mentioned in the advantages and disadvantages of the hydraulic system, this working principle will indeed greatly facilitate the transfer of heavy material. However, hydraulics also need intensive and periodic maintenance to ensure their normal function. If heavy equipment with a hydraulic pump working is used every day, then this is what you should do:

1. Check the oil level in the tank, fill it when it is reduced.

2. Check the foam on the surface of the working liquid to make sure it's air or water.

3. Detection of leaks in drains and connections.

4. View and check the operation of the temperature stabilization system.

5. Control the filter contamination level indicator.

6. Check the valve setting on the pressure gauge.

7. Check the electromagnetic supply voltage of the control device.

If your work is related to heavy equipment, please take the information about the advantages and disadvantages of this hydraulic system as a consideration. If you need lifting magnets to make your daily work easier, you can get them at Hyprowira. There are also hydraulic pressure booster products that can increase the lifting capacity of the machine.