The saturation point is the maximum amount of dissolved water that oil can contain, it depend on the oil’s temperature, age and additive composition. The higher the temperature, or the saturation point the more water in the dissolved phase.

Why is water considered destructive, water contamination in fluid systems causes:

- Fluid breakdown, such as additive precipitation, oil oxidation, acid formation, thickening, varnish & sludge.

- Cavitation, foaming & air entrainment problems.

- Reduced lubricating film thickness leading to accelerated metal surface fatigue.

- Corrosion.

- Bacterial & fungal growth.

- Poor filterability & valve stiction.

- Reduced dielectric properties.

- Icing.

The solubility of water in oil varies depending on the temperature & oil type. It is depicted on a saturation curve, e.g.:

Typical sources of water ingress

· Through system vents / breathers.

· From leaking coolers and heat exchangers.

· Through leaking seals & reservoir covers.

· Condensation.

· Precipitation of dissolved water due to a fall in temperature.

· Introduction of contaminated top-up fluid.

· Rain leaking into incorrectly stowed barrels & external reservoirs

Top 4 Water in Oil Removal Technologies, from inexpensive gravity separation to complex vacuum dehydration, exist to remove water. The most effective technology will depend on :

1. Target dryness level required

2. The volume of water that must be removed

3. Type base oil

4. Flow and process rate

Centrifuge

Separations of oil and water by spinning the oil to create high G-forces. The greater the difference in specific gravity between water contaminant and the oil, the more effective the process. The lower the oil’s temperature, the more effective the removal process.

Centrifuge only remove the free water from the oil.

Absorbing

Only removes free & emulsified water and not suitable for high water ingress applications (limited water holding capacity)

Coalescer

Coalescers can remove large amounts of free water from suitable oils with high interfacial tension

Can only remove free water (& contaminant)

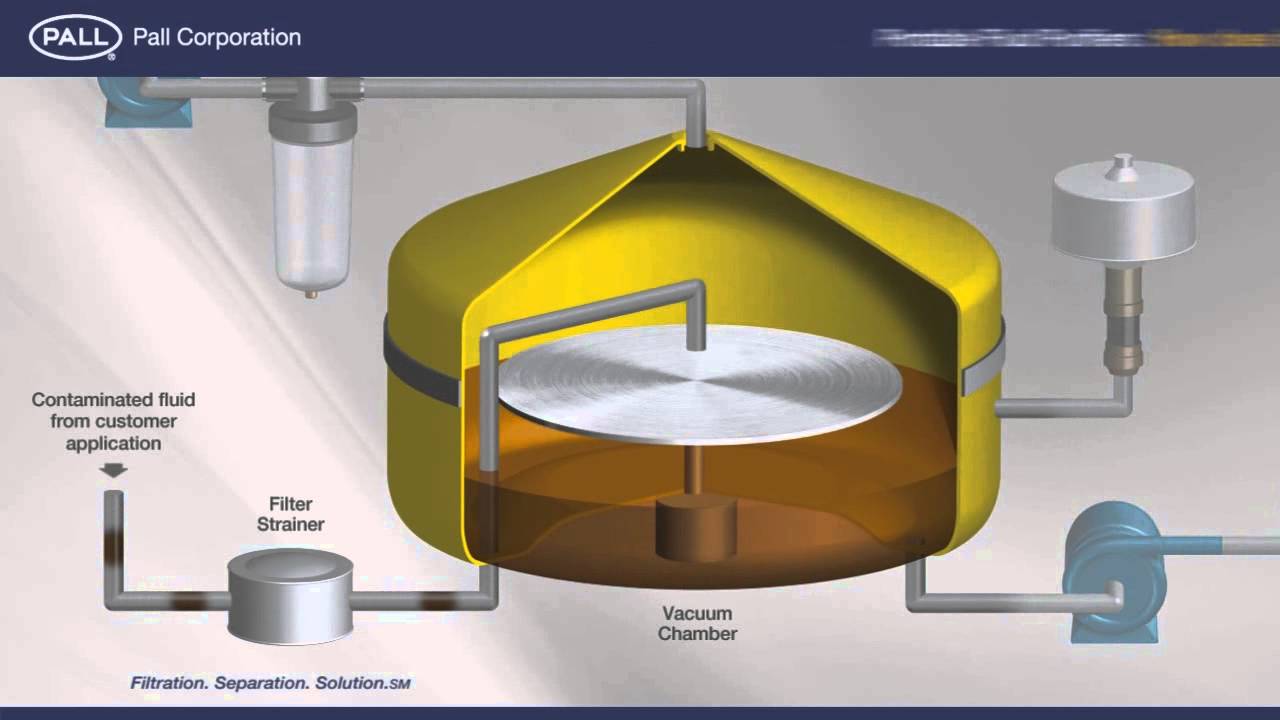

Vacuum Dehydration

Similar to a tumble dryer where the flow of dry air removes moisture from clothes

Expansion to vacuum reduces RH of incoming air to make it very dry

Uses lower temperatures & vacuums but higher dry air flows to remove moisture by evaporation – multipass operation with much less stress on oil

Comparations of Water Removal Technology